An Alexandria man, C.C. Hall, is considered the “father of the rock wool industry” in America.

After inventing a process that used limestone to make insulation, he established the Banner Rock Company in 1906 in Alexandria. It was the first factory to profitably produce an ideal insulation for the construction industry. Today, he merits an entry in the history section of the online website, “Today in Science.”

Rock wool, also known as stone wool or mineral wool, is made by forcing steam through molten rocks or minerals. The spun fiber resembles clumps of sheep wool; it is ideal as insulation for cold, heat and sound. It is fireproof, is resistant to vermin and compacting, and does not disintegrate.

Mineral wool was first manufactured in the 1800s using steel slag, the scum left on the top of molten steel, but it disintegrated quickly, had a noxious odor and caused breathing problems among workers.

Charles Corydon Hall, a chemical engineer originally from Massachusetts, came to Alexandria with his family in 1897 to supervise construction of a steel rolling mill.

While in Pittsburgh that year, he had witnessed the production of mineral wool from steel slag, but noted the drawbacks of the material. While returning to Alexandria, he hit upon the idea of using the area’s limestone to produce rock wool by the same process. This avoided the sulfur in steel, which he considered the source of the defects.

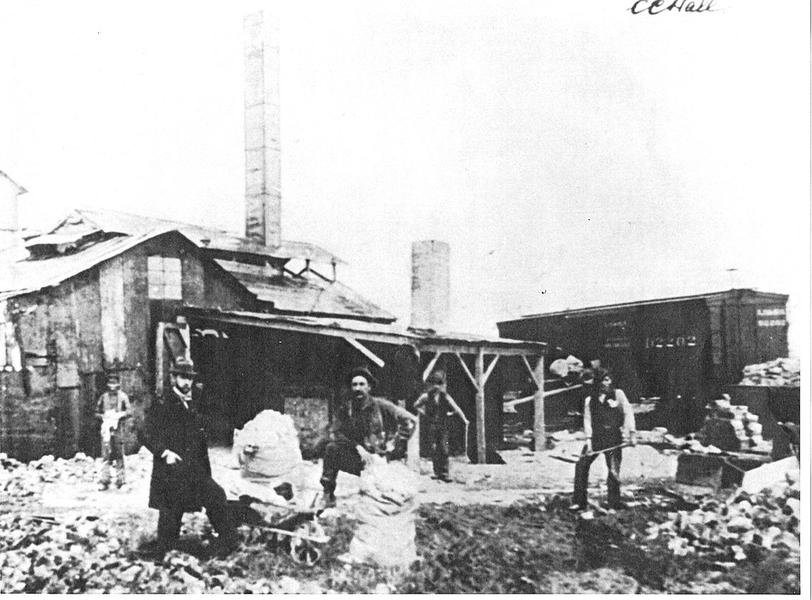

When the steel mill failed to open due to the falling supply of cheap natural gas in east central Indiana, Hall remained in Alexandria. He raised $1,000, and using a ramshackle building on the site of the steel plant, began several years of experimentation to determine the best equipment and procedures for turning out rock wool insulation made with limestone quarried near the city.

The quarrying of limestone to make rock wool created many of the water-filled pits near Alexandria. While in business, Hall bought options on several hundred acres to be used as future quarries.

Hall formed the Chemical Crystal Company in 1902 with two Alexandria businessmen. He continued experiments and worked on building a market. He developed a wallboard which he called “rock cork.”

The majority partners later sold the plant, but he stayed only briefly before breaking away to form the Banner Rock Company in 1906 with new investors. Plant Number One was built at the end of town on West Washington St. in Alexandria. Hall built Plant Number two across the street in the 1920s. He employed up to 200 people.

Hall developed a market for rock wool by advertising its qualities.

It simultaneously met several building code requirements, in that it was fireproof and at the same time provided insulation against both heat and cold. It did not disintegrate or compress, and resisted vermin. It also provides acoustic insulation; it has been used since the advent of talkies for sound insulation in movie studios.

Though commonly thought of as insulation for house wall and attics, rock wool has many other applications. It is used as a coating on industrial ovens and piping, in refrigeration units, as a heat barrier in vehicles from planes to ships to automobiles, in motors, and even in small appliances like toasters and blenders.

It will absorb water if not protected, but this became an asset in the late 20th century when it was developed as a medium for sprouting seeds.

Even though C. C. Hall worked hard to develop the Banner Rock Company, he was involved in his church and the community in many ways. He ran unsuccessfully for mayor in 1905. He enjoyed taking roles in locally produced musical comedies.

Hall never stopped trying to produce better rock wool. It was said in Alexandria that his wife rarely had her kitchen oven available for baking because Hall so often used it to “bake” his latest experiments.

Hall and his wife raised one son and three daughters in Alexandria. (Another son had died at the age of 4.) They had a large and lively home. A new neighbor once remarked that when he looked across the street, he thought the house must be a girls’ school because there were so many girls on the front porch.

Hall’s wife, Julia Stith Hall, the mother of his children, died in 1910, and in 1914, he married Carrie Scott.

His son, Corydon H. Hall, also a chemical engineer, became treasurer of Banner Rock in 1920. He began working for Johns-Manville when it bought out Banner Rock in 1929. The younger Hall had a long career in upper management with JM.

At the time of the sale to JM, the Alexandria Times Tribune praised the elder Hall as a man who put his community first, and as a businessman who used local workers and local supplies. In addition to “The Best Little City,” the town by that time had begun billing itself as “The Home of Rock Wool.”

When he died at the age of 75, on Aug. 19, 1935, C.C. Hall was honored as an inventor, a good family man, and a public-spirited citizen. The mayor issued a proclamation urging the town’s businesses to close during the funeral so that all could pay their respects.

Shortly after his death, the Times-Tribune published a letter he had written about his early experiments to a student doing a paper at the University of Wisconsin. The student later became an employee of the Tribune and shared the letter with the public.

In the 1930 letter, C.C. Hall remarked that the years from 1906-1916 were difficult, as the market for rock wool built up slowly, but that he never lost faith in the product. He called it “argillaceous limestone,” a mixture of limestone, clay, and other ingredients. He added that the United States and Canada had a few plants that still produced mineral wool from steel slag, but that the rock wool from limestone “is distinct in its service and really the only form of commercial importance.”

Today, rock wool is again being made from handy and cheap steel slag, since the process has been perfected, but the industry still mixes in limestone, basalt, and other crushed rocks. “Glass wool” or “fiberglass,” is a major insulation product but is not as safe as rock wool for many applications.

Today, more than 100 years after C.C. Hall began producing it, rock wool is the manmade mineral fiber most used worldwide for insulation. It is environmentally safer than other insulation because it doesn’t break down and can be recycled. Most important of all, it does not contain asbestos and cannot cause cancer.

Other insulation making companies that called Alexandria home were: National Gypsium, Rockwool Industries, Banner Rock, and John Mansville.